Contact: Allen zhang

Mobile: +8618657301314

Tel: +86-573-88236564

QQ: 307160103

Email: allen@aramid.biz

Address: Tongyuan Road, Tongfu Industrial Park, Tongxiang City, Zhejiang Province

Website:en.surefrp.com

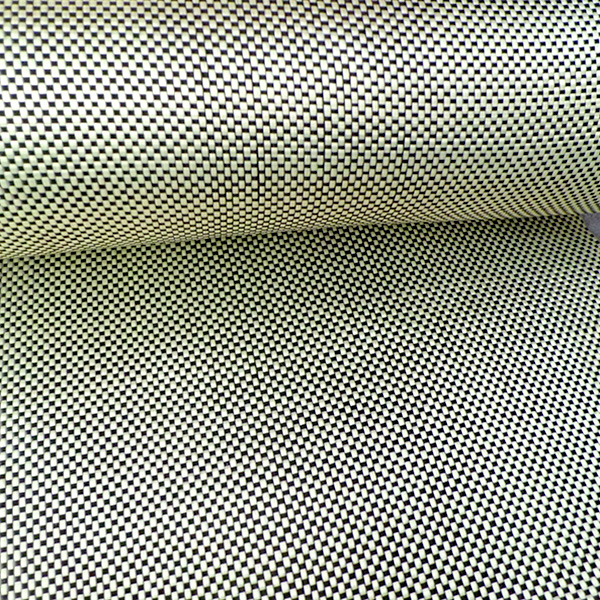

Aramid is called "polyphthaloyl phenyl diamine", English is Aramid fiber (trade name of Teijin aramid is Twaron DuPont company under the trade name Kevlar), is a new high-tech synthetic fiber with high strength, High modulus and high temperature resistance, acid and alkali resistance, light weight and other excellent properties, the strength is 5 to 6 times that of steel wire, the modulus is 2 to 3 times that of steel wire or glass fiber, the toughness is twice that of steel wire, and the weight is only It is about 1/5 of the wire, and does not decompose at 560 degrees, and does not melt.

It has good insulation properties and a long life cycle. The discovery of aramid is considered to be a very important historical process in the material world.

Twaron's production requires three processes: polymerization, filament spinning and tow spinning.

Polymerization

In the first stage, the monomer is first spun into a fine fine particle polymer powder. This material has the main thermal and chemical properties of para-aramid. However, it does not have the reinforcing properties of yarn or pulp. This fine powder can be used to enhance the properties of the plastic component.

2. Spinning

In the second stage, the polymer is dissolved in sulfuric acid to form a liquid crystal solution. The solution was then spun into filaments each having a diameter of 12 μm. The structure of the filament is subcrystalline, and the molecular chain is parallel to the fiber axis. Formal such a high tendency distribution gives Twaron filaments various excellent properties.

In order to produce staple fibers or chopped fibers, the yarn is now creped and then treated with a finishing agent. After drying, the fibers are cut to the target length and then packaged.

4. Spinning into pulp

To produce pulp, the yarn is first cut and then the yarn is suspended in water for fiberization. It is then packaged directly and sold as wet pulp, or dehydrated and dried for sale as a dry pulp.

Contact: Allen zhang

Mobile: +8618657301314

Tel: +86-573-88236564

QQ: 307160103

Address: Tongyuan Road, Tongfu Industrial Park, Tongxiang City, Zhejiang Province

Website:en.surefrp.com